Learning from Neural Networks

Rebal Jaber

Darayya, Syria

The strangler fig tree is a unique specie, whose behaviour is vital in its search for habitats to grow, affected by the neighbouring and exemplified in finding the shortest path to get food. By understanding the rules of these behaviours, we can devise a design that follows a set of procedures based on a structural performance that can be constructed by simulating natural systems as an alternative to the usual use of stylistic symbols in design. Using nature's testing and modelling, as a source for learning and problem solving, we can design systems for efficiency and optimisation.

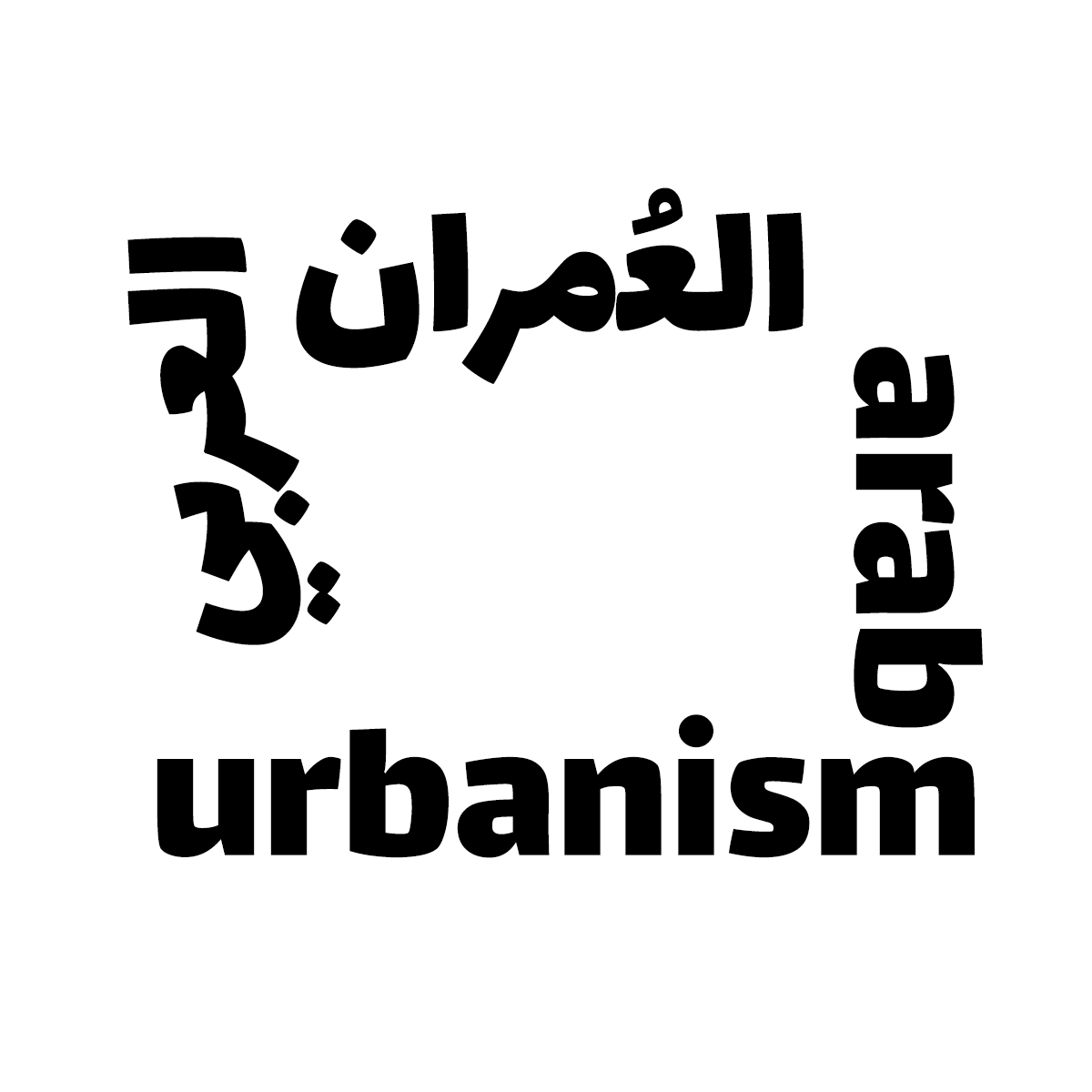

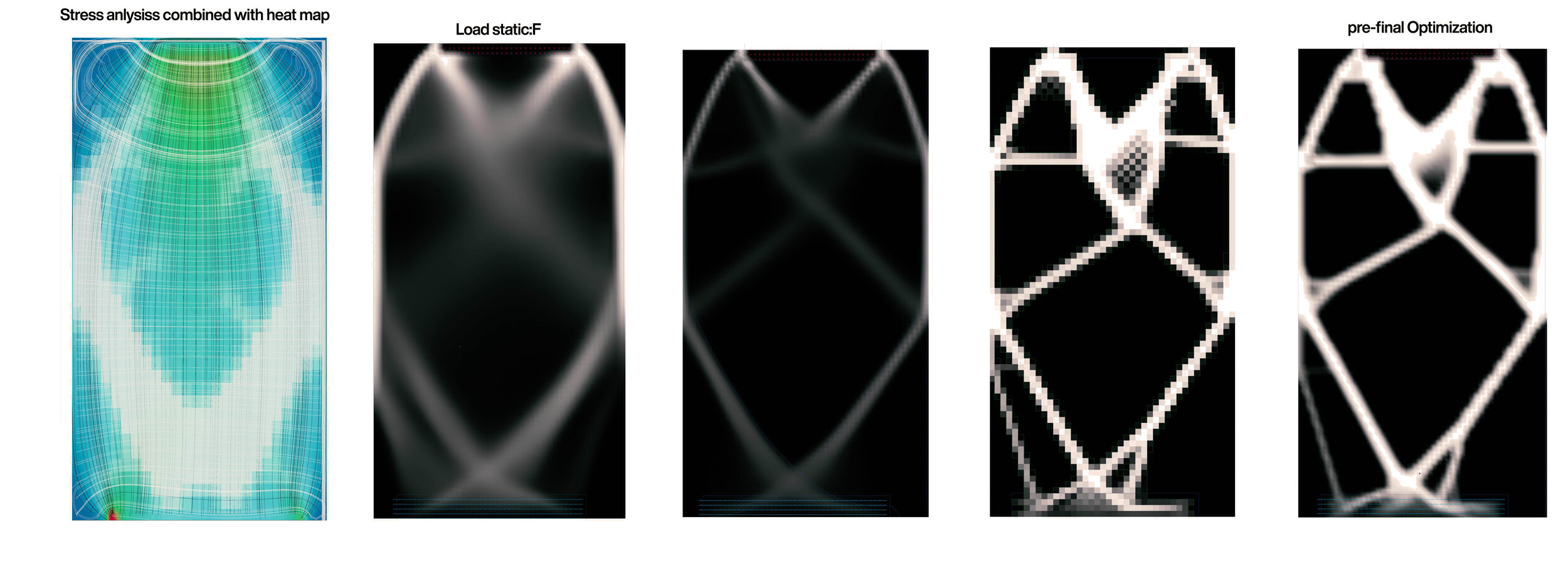

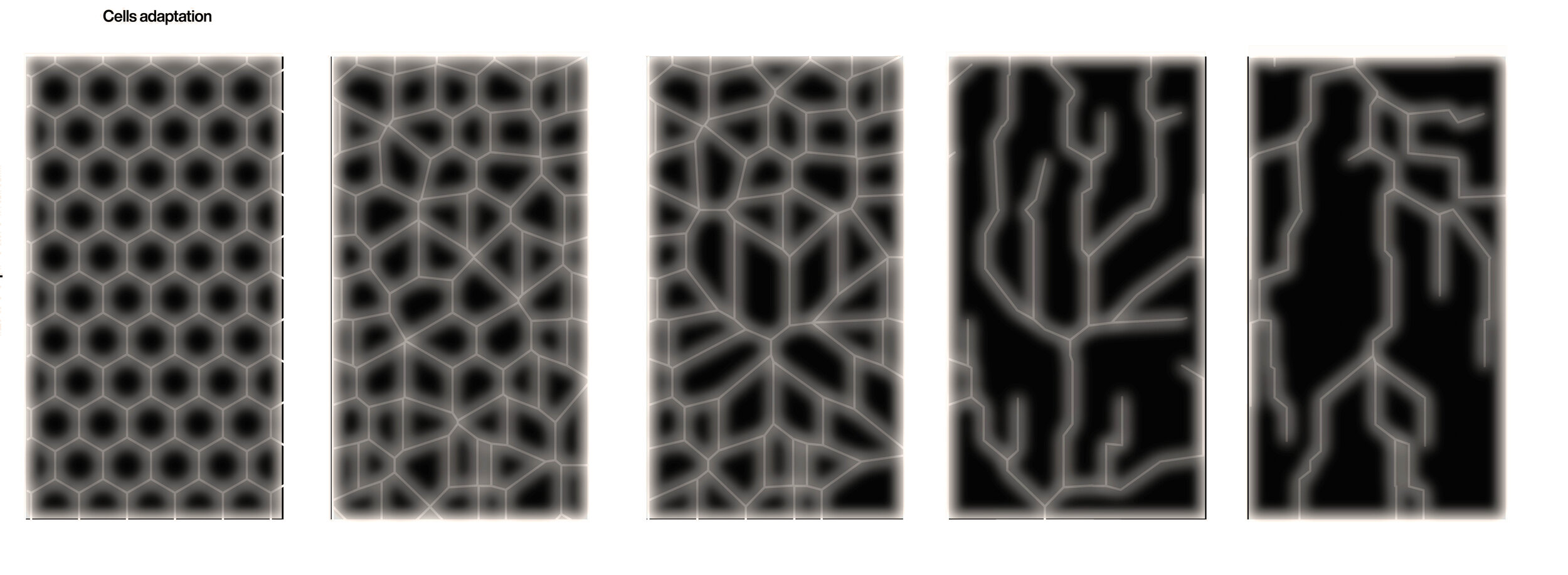

Experimenting with neural networks is regarded as one of the most notable in this field. It’s based on designing a syllabus that generates adaptive elements within any containing mass, forming design alternatives to many architectural elements such as columns and walls. This approach consists of two steps. First, to reduce the effect of the material mass and cost by optimising the mass to respond to the areas of loads. This was done by using Finite element analysis FEA and topology optimisation tools resulting in a lighter structure. Second, after finding a general map for the mass topology, the mass is retraced using self-organising decentralised systems which are very similar to the mechanisms of the Strangler tree structures. In these systems, centralised behaviour is replaced by individual agents interactions at a local level. This operation was made by iterative application of stigmergy algorithm that is similar to the algorithm that simulates Ant Colonies Optimization (ACO).

Figure 1. Final Mesh for Steel Joint

Figure 2. Steel Joint Model Rendering

The panels produced by this experiment have been made within our series of research-oriented sculpturing “Traces of Nature”. Beech and walnut wood panels were brought and prepared in an area near the town of Daraya in the countryside of Damascus. In addition to machines, the master carpenters Adnan Al-Muallem, Khalil Shuaib and Ayman Zardah worked on the pieces. The project has exhibited a new possibility to the wood making and furniture industry in Syria. The difficulty and the limitation of resources to produce complex three-dimensional surfaces was overcame through a collaboration between the manual and the digital. The available Computer Numerical Control (CNC) Machines could do two-dimensional carving only. A set of tools that changes from smoothing and carving have translated the coordinates of the organic surface and replaced the need for three-dimensional carving. The panels were chosen to be displayed at the Beirut House Museum during Beirut Design Week 2018. The (Digital Gallery) exhibition was curated by Ghassan Salamé.

The projects necessitated a team of experts in the field of manufacturing and materials. It has not been possible to do this work without the participation of talented designers who were involved in the project, namely: Muhammad Zanbou’a, Tala Al Shami, Omar Sallakh, Hisham Telo, and the Engineer Maan Al-Sham.

As for the future, advanced techniques such as rapid manufacturing “additive manufacturing” can be used by adding layers of metal one after another as they produce architectural details that can be used directly on-site, saving a lot of material and time.

Figure 3. Neural Networks project at Beirut Design Week 2018. Photography by Taim Karessly-Adorno.